Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |DELTA WW OF-HSX

High performance, energy saving, and sustainability are the key aspects of IMA Ilapak cutting-edge solution, that is available also in Atex configuration for high alcoholic lotions and in full Electric version.

High performance, energy saving, and sustainability are the key aspects of IMA Ilapak cutting-edge solution, that is available also in Atex configuration for high alcoholic lotions and in full Electric version.

First-class flow wrapper

High-speed flow wrapping platform with open frame structure specially designed to meet the wet wipes industry needs. The range includes two models, Delta WW OF-HS and HSX, where the HS version can also be upgraded and implemented at a later stage to achieve top-end HSX’s features and performances.

The Delta WW OF-HSX can be set up, as an option, as a fully ATEX compliant machine.Available also in the 100% electric version – without pneumatic features- this flow wrapping platform is equipped with ultrasonic longitudinal sealing system and last generation sealing head with special profile jaws suitable for new generation sustainable materials.

Sustainability

Energy saving, thanks to less heating, and sustainability are the key aspects of this cutting-edge solution, capable to ensure with the same configuration of the sealing elements, up to 170 ppm with traditional laminated films and up to 130ppm with fully recyclable materials.

DELTA WW OF-HSX Highlights

- Technical Data

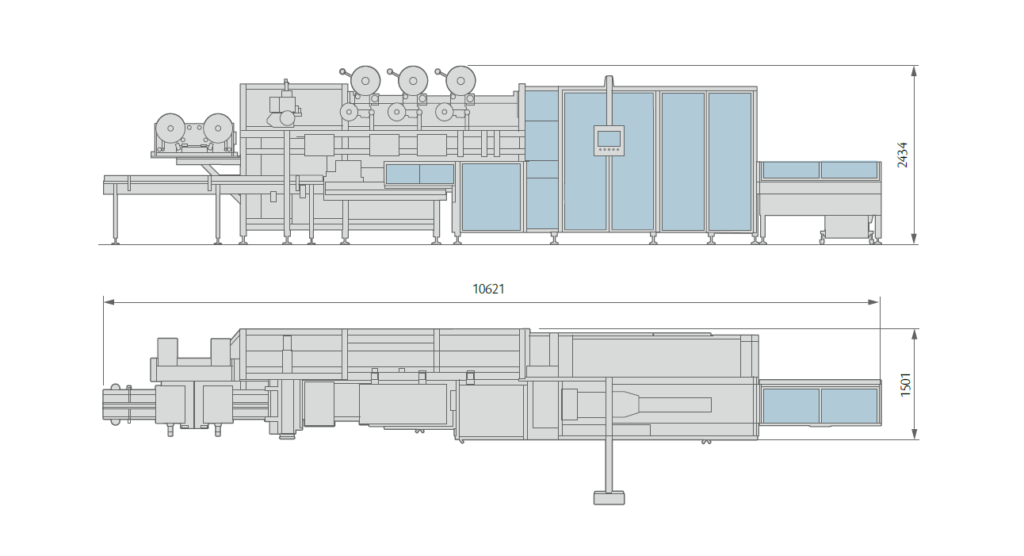

- Machine Layout

| TECHNICAL DATA | |

| Machine Speed | Up to 170 ppm, single jaw. Production output dependent upon product, film and machine specifications |

| Film Cut-Off | Min 100 mm – 4.0” / Max 500 mm – 47” Depending on film and product characteristics |

| Wrapping Materials | Laminated, recyclable materials (mono-material), co-extruded and all sealable films |

| Film Reel Max Weight | 40 kg – 88 lbs |

| Electronic Platform | Industrial PC Other electronic control platform on request i.e. Allen Bradley |

| Power Requirement | From 220 to 480V, 50/60 Hz, 3-phase, 22kW |

| Compressed Air | 6 bar, 200 nl/min |

| Machine Weight | 1400 Kg – 3100 lbs |

| PRODUCT DIMENSIONS | |

| Length | Up to 400 mm – 15.7” standard |

| Width | Up to 150 mm – 5.9” (jaws 190 mm – 7.5”) |

| Height | Up to 100 mm – 4.0” standard |

| FILM REEL DIMENSIONS | |

| Core ø | 76 mm – 3” |

| Outer ø | 400 mm – 15.7” for film reel web width up to 500 mm/ 19.7” |

| Width | 500 mm – 19.7” |