Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |CA 3

The newly designed CA3 monobloc machine for boxed, heat-sealed pods integrates an advanced dosing and compression system enabling even distribution of coffee inside the pod and a precise pod profile, and can easily connect to alternative end-of-line machines.

The newly designed CA3 monobloc machine for boxed, heat-sealed pods integrates an advanced dosing and compression system enabling even distribution of coffee inside the pod and a precise pod profile, and can easily connect to alternative end-of-line machines.

Makes the difference

The CA3 packs both soft and hard coffee pods in a modified and conditioned atmosphere, heat-sealing them in a protective outer envelope and finally packing them into cartons at a production speed of 250 pods/minute.

The production cycle of the machine is completed by an integrated, fully automatic, accessible and adjustable cartoning unit.

Prior to being inserted into a heat-sealed outer envelope, a controlled supply of nitrogen is introduced into a protective hood, where humidity and temperature are kept unvaried to guarantee optimum product quality.

Sustainability

The CA3 can handle compostable and recyclable materials (filter paper, envelope).

CA 3 Highlights

- Technical Data

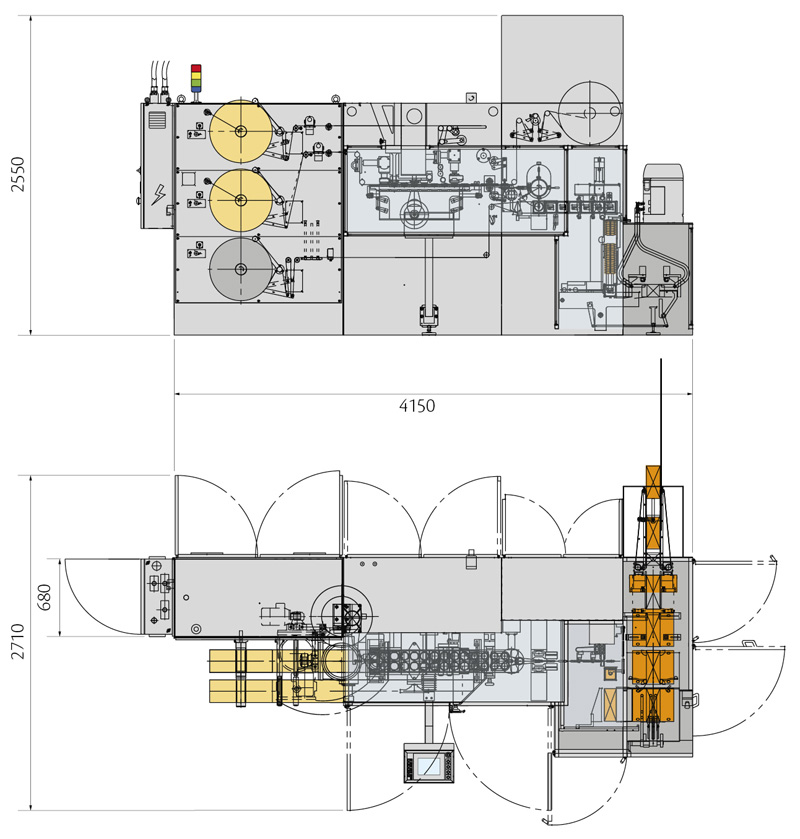

- Machine Layout

| CA3 TECHNICAL DATA | |

| Machine speed (Coffee pod/minute) | Up to 250 |

| Pod capacity | Up to 14 grams of coffee |

| Power required | Total installed power max. 20 kW |

| Power consumption | 14 kW |

| N.b. Consumption depends on the thermics group fitted on the machine | |

| Compressed air | Duty pressure: 6 bar – consuption 250 Nl/min. |

| Machine net weight | Max. 4,000 Kg |

| Data subject to possible technical modification and not necessarily definitive | |

Related products

Array

(

[cover_macro] => 1460

[cover_name_type] => txt

[cover_name] => CA1

[cover_descriptor] => Soft pod packaging

[cover_focus_on] => 1

[news] =>

[thumbnail] => 4529

[tag_line] => A soft pod packaging line in one single machine

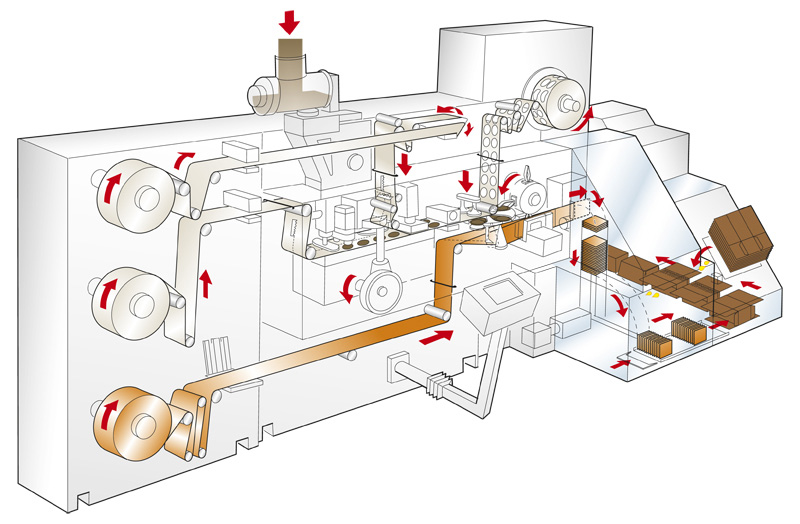

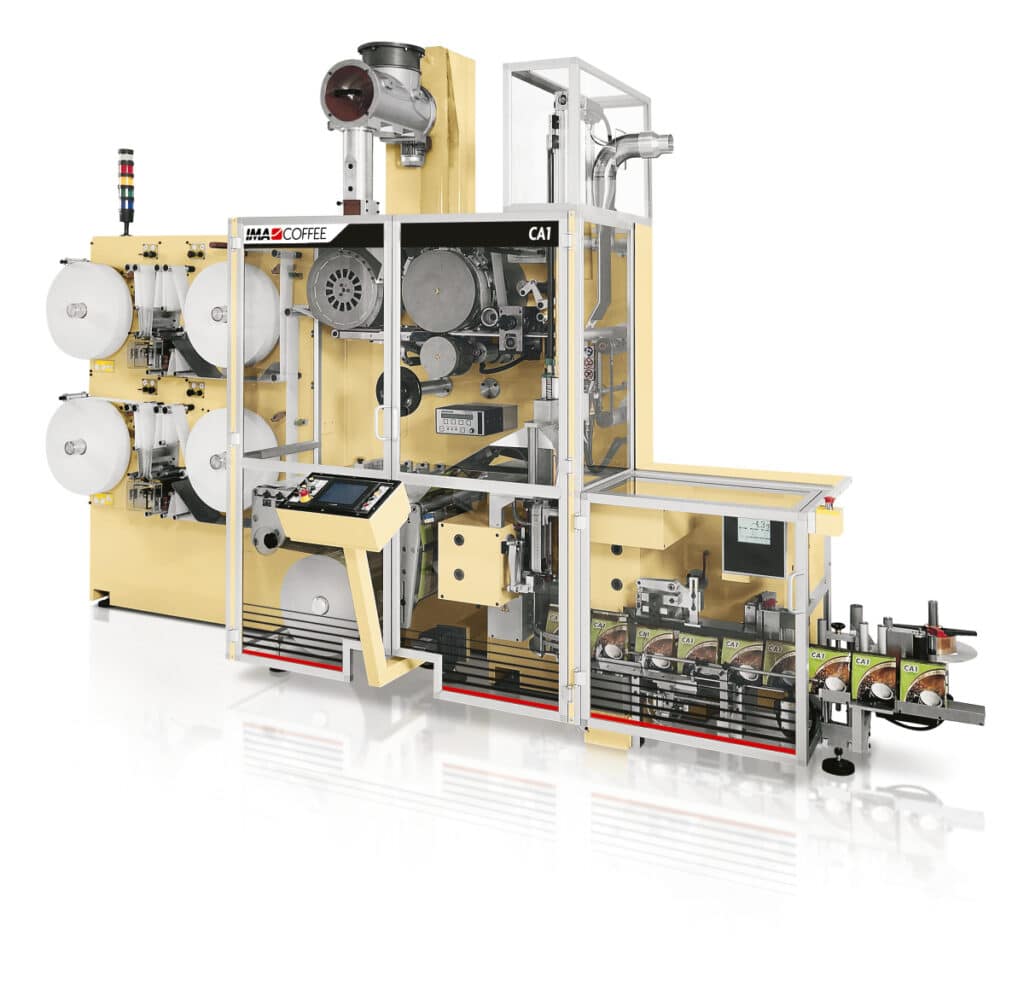

[overview] => The CA1 is a unique, high-speed machine able to produce soft pods in one single lane, counted, stacked and packed into a block bottom bag.

Auxiliary units for pod counting, stacking, pack forming, filling, closing and weight-checking all fit into little more than a 4.3 metre length layout, making the CA1 an efficient, comprehensive and extremely compact machine processing up to 800 soft pods/minute.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

The CA1 can handle compostable and recyclable materials (filter paper, envelope).

[highlights_on] => 1

[focus_on] =>

[technical_data] => | TECHNICAL DATA CA 1 | |

| Machine speed (coffee pod/minute) | Up to 800 |

| Capacity coffee pod | Up to 14 grams of coffee |

| Heatsaled pack capacity | Min. 8 – Max. 18 pods per pack |

| Power required | Total installed power 23 kW |

| Power consumption | 18 kW |

| N.b. Consumption dipends on the thermics group fitted on the machine | |

| Compressed air | Duty pressure: 6 bar – Consumption: 200 Nl/min. |

| Machine net weight | Max. 4,500 Kg |

| Data subject to possible technical modification and not necessarily definitive | |

The CA1 all-in-one, single-dose coffee packaging machine takes efficiency to new heights, guarantees maximum flexibility and quick changeover procedures, user-friendly operation and saves on packaging material.

[buttons_on] => [cover_focus_buttons] => Array ( [buttons_on] => [view_default] => 1 [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => contact us [icon] => mail [form_email] => sales.coffee@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) ) [highlights] => Array ( [0] => Array ( [highlight] => Gas flushing unit to avoid coffee oxidation and maintain flavour - low oxygen residue (<1%). ) [1] => Array ( [highlight] => Automatic filter paper splicing system: smooth and without need to reduce speed for maximum efficiency. ) [2] => Array ( [highlight] => Programmable electronic counting system: ensures correct number of pods in stacking unit at all times. Can switch from 1 to 2 pod stacks. ) [3] => Array ( [highlight] => CA1 is a lubrication-free machine for cleaner processing. ) [4] => Array ( [highlight] => Numerous optional groups available for maximum packaging versatility. ) ) [rel_market] => Array ( ) [clone_list] => Array ( ) [contact] => sales.coffee@ima.it [no_index] => [versions_on] => 1 [addon_on] => [versions_thumbnail] => 1471 [versions_tag_line] => Integrated coffee grinder [versions_overview] =>Simple installation of an integrated coffee grinder onto the machine’s product hopper is a way of completing the production cycle of the CA1 without extending the footprint beyond the space-efficient 4.3 metre length layout.

[versions_overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [market_products] => Array ( [0] => 617 ) [market_packs] => Array ( [0] => 2215 ) [market_brands] => Array ( [0] => 37959 ) [market_plants] => Array ( [0] => 37959 ) [line_step] => Array ( [0] => 7 ) [tile_description] => [tile_speed] => Up to 800 pods/min [aseptic] => both [thread_tag] => coffee [market_packs_specs] => Array ( ) [output_on] => [body_class] => [no_follow] => [seo_image] => [seo_title] => [seo_description] => [embed_iframe] => [form_price] => [view_default] => 1 [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => contact us [icon] => mail [form_email] => sales.coffee@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) [versions_title] => [versions] => [related] => no [technologies] => Array ( [0] => 77 ) [canonical_url] => )

The CA1 all-in-one, single-dose coffee packaging machine takes efficiency to new heights, guarantees maximum flexibility and quick changeover procedures, user-friendly operation and saves on packaging material.

Array

(

[cover_macro] => 1435

[cover_name_type] => txt

[cover_name] => CA6

[cover_descriptor] => Hard pod packaging

[cover_focus_on] => 1

[news] =>

[thumbnail] => 4527

[tag_line] => Essential solutions, essential quality

[overview] => The CA6 packs hard coffee pods in a modified and conditioned atmosphere, heat-sealing them in a protective outer envelope and finally packing them into cartons at a production speed of 130 pods/minute.

Clever modular design facilitates accessibility for size changeovers and maintenance. Specially conceived elements contribute to achieving interesting savings: the reduced space between one group and the other in the pod forming stations helps limit both filter paper consumption as well as waste paper.

Furthermore, precisely controlled mechanical introduction of the filter paper pod into the outer envelope allows the size of the outer envelope to be considerably reduced, thus saving on heat-sealable material.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

The CA6 can handle compostable and recyclable materials (filter paper, envelope).

[highlights_on] => 1

[focus_on] => 1

[technical_data] => | TECHNICAL DATA CA6 | |

| Machine speed (Coffee pod/minute) | Up to 130 |

| Pod capacity | Up to 14 grams of coffee |

| Power required | Total installed power max. 11 kW |

| Power consumption | 7.3 kW |

| N.b. Consumption depends on the thermics group fitted on the machine | |

| Compressed air | Duty pressure: 6 bar – consuption 250 Nl/min. |

| Machine net weight | Max. 3,100 Kg |

| Data subject to possible technical modification and not necessarily definitive | |

Producing hard coffee pods on a single line, the CA6 is the simplest, most compact monobloc solution available today. The essential design of the entire line ensures a considerable reduction in terms of power consumption and top rate efficiency.

[buttons_on] => [cover_focus_buttons] => Array ( [buttons_on] => [view_default] => 1 [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => contact us [icon] => mail [form_email] => sale.coffee@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) ) [highlights] => Array ( [0] => Array ( [highlight] => Pre-assembled units for size changeover: greater speed and less downtime thanks to fewer on-machine adjustments. ) [1] => Array ( [highlight] => Production cycle controlled by integrated PC: ensures correct operation and final product quality. ) [2] => Array ( [highlight] => Can be equipped with an exit belt complete with flip-flop and programmable count for the bulk filling of pods into cartons or bags. ) [3] => Array ( [highlight] => CA6 is a lubrication-free machine for cleaner processing. ) ) [focus] => Array ( [image] => 1439 [content] => A special dosing unit, with a constantly regulated servo-controlled auger prior to mechanical compression station, ensures even distribution of coffee inside the pod as well as a uniform compression, making for a perfect pod with a clean, precise profile. [buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) ) [rel_market] => Array ( ) [clone_list] => Array ( ) [contact] => sales.coffee@ima.it [no_index] => [versions_on] => [addon_on] => [thread_tag] => coffee [tile_description] => [tile_speed] => Up to 130 pods/min [output_on] => [line_step] => Array ( [0] => 7 ) [aseptic] => both [market_products] => Array ( [0] => 617 ) [market_packs] => Array ( [0] => 2215 ) [market_packs_specs] => Array ( ) [market_brands] => Array ( [0] => 37959 ) [market_plants] => Array ( [0] => 37959 ) [no_follow] => [seo_image] => [seo_title] => [seo_description] => [embed_iframe] => [form_price] => [body_class] => [view_default] => 1 [buttons_items] => Array ( [0] => Array ( [acf_fc_layout] => private [button_id] => [button_class] => [text] => contact us [icon] => mail [form_email] => sale.coffee@ima.it [type] => contact [private_product] => [private_exhibition] => [form_type] => contact [form_id] => ) ) [related] => no [technologies] => Array ( [0] => 77 ) [canonical_url] => )

Producing hard coffee pods on a single line, the CA6 is the simplest, most compact monobloc solution available today. The essential design of the entire line ensures a considerable reduction in terms of power consumption and top rate efficiency.

Array

(

[embed_iframe] =>

[form_price] =>

[contact] =>

[no_index] =>

[thread_tag] =>

[tile_description] => WRAP AROUNG CASE PACKING MACHINE. Electronically driven, high-performance wrap around case packer, the MMP400 benefits from astute ergonomic design features enabling user-friendly operation and optimum productivity, with a flat blanks magazine positioned to allow easy case loading.

[tile_speed] => 30 cycles/min.

[cover_macro] => 3661

[cover_name_type] => txt

[cover_name] => MMP400

[cover_descriptor] => Wrap around case packing machine

[cover_focus_on] => 1

[news] =>

[thumbnail] => 3624

[tag_line] => Smart solutions catering for all Coffee packagings

[overview] => Built to pack individual or bundled products into cases, display boxes or trays starting from flat blanks or pre-glued cases, the MMP400 wrap around case packer has been engineered to protect and preserve the highest integrity of the content. This system is so effective, it allows to handle all kinds of coffee containers: from single serve capsules to bags.

The MMP400 features servo technology enabling speeds of up to 30 cases/minute and extremely smooth handling.

Ergonomically positioned components help to significantly improve operator intervention and thanks to a newly designed case erection mechanism, the horizontal case magazine is as low as possible to achieve increased autonomy. Cases are erected and held in position on two sides during loading.

[overview_buttons] => Array

(

[buttons_on] =>

[view_default] =>

[buttons_items] =>

)

[sustainability] =>

[highlights_on] => 1

[focus_on] =>

[versions_on] => 1

[addon_on] => 1

[output_on] =>

[technical_data] => | TECHNICAL DATA MMP400 |

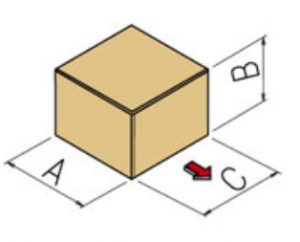

| MMP400 | A | B | C |

| Case dimensions (MIN) | 80 | 80 | 140 |

| Case dimensions (MAX) | 420 | 325 | 420 |

| MMP600 | A | B | C |

| Case dimensions (MIN) | 80 | 80 | 250 |

| Case dimensions (MAX) | 420 | 325 | 600 |

| Speed: up to 30 cases/min |

Electronically driven, high-performance wrap around case packer, the MMP400 benefits from astute ergonomic design features enabling user-friendly operation and optimum productivity, with a flat blanks magazine positioned to allow easy case loading.

[buttons_on] => [cover_focus_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [highlights] => Array ( [0] => Array ( [highlight] => Independent modules on infeed to allow for the efficient handling of all kinds of coffee containers: pillow bags, sticks, envelopes, block bottom bags, flowpacks, dispensing boxes, pre-glued boxes, filp top boxes, jars, capsules. ) [1] => Array ( [highlight] => Flexible machine offering the widest range of packaging solutions: wrap-around cases, RSC cases, trays, trays with internal or external hood and display boxes. ) [2] => Array ( [highlight] => Machine fully servo equipped. ) [3] => Array ( [highlight] => New 830 mm height case magazine for easy loading of cases, equipped with two driven belts to store display boxes with irregualr shapes. ) [4] => Array ( [highlight] => Can be equipped either with a 6 axes robot or with a 2 axes loading system (pusher or pick&place), allowing for efficient handling of any products even if they are unstable or critical to run at high speed. ) [5] => Array ( [highlight] => Cantilever design for optimum accessibility and easy cleaning. ) [6] => Array ( [highlight] => Internal or external lid unit available. ) [7] => Array ( [highlight] => MMP600 version available for bigger case sizes (C/width dimension up to 600mm) ) ) [body_class] => [no_follow] => [seo_image] => [seo_title] => [seo_description] => [versions_thumbnail] => 3634 [versions_tag_line] => Wrap around case packer - palletizer integrated versions [versions_overview] =>MMP400 is available in different palletizer-integrated versions, according to the output speed required.

[versions_overview_buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) [focus] => Array ( [image] => [content] => At IMA BFB we have combined our knowledge and experience in handling a wide variety of shapes and developed different infeed systems to allow for the efficient handling of all kinds of products even if they are unstable or critical to run at high speed. [buttons] => Array ( [buttons_on] => [view_default] => [buttons_items] => ) ) [related] => no [technologies] => Array ( [0] => 105 [1] => 108 ) [addon_title] => Good To Know [addon_items] => Array ( [0] => Array ( [image] => 4597 [description] => Thanks to its modular design the MMP400 can be easily equipped with different modules on infeed. A host of solutions are available to handle any kind of coffee container. Whatever the shape or the size of the bags, cartons and capsules may be, the integrity of the content is always preserved, the quality of the final packaging is guaranteed. ) ) [versions_title] => [versions] => )