Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |E-CO FLEX CLOSING

The standalone closing module of the E-CO FLEX platform is provided with the down-sizing function, which automatically re-sizes the box height.

The standalone closing module of the E-CO FLEX platform is provided with the down-sizing function, which automatically re-sizes the box height.

Cut and close FEFCO 201 boxes automatically.

After the product is inserted, the open-faced case can be placed into the E-CO FLEX CLOSING module, which can operate as automatic standalone equipment. A bank of ultrasonic sensors measures the remaining void within the box. If the system detects the possibility to reduce the height, the enclosed down-sizing group will automatically cut the four corners of the box (up to 270 mm). This allows the case flaps to adapt to the new box dimensions when closed, reducing its height up to 20-25%.

The cases can be sealed on top with sustainable water-activated tape.

The machine is designed to detect the SIOC cases and automatically bypass them.

The E-CO FLEX CLOSING module can be equipped, as option, with a Print & Apply labeller and quality inspection cameras to check flaps folding and taping.

If you are in search of an integrated solution for case erecting and closing, click to discover our E-CO FLEX PACKING STATION

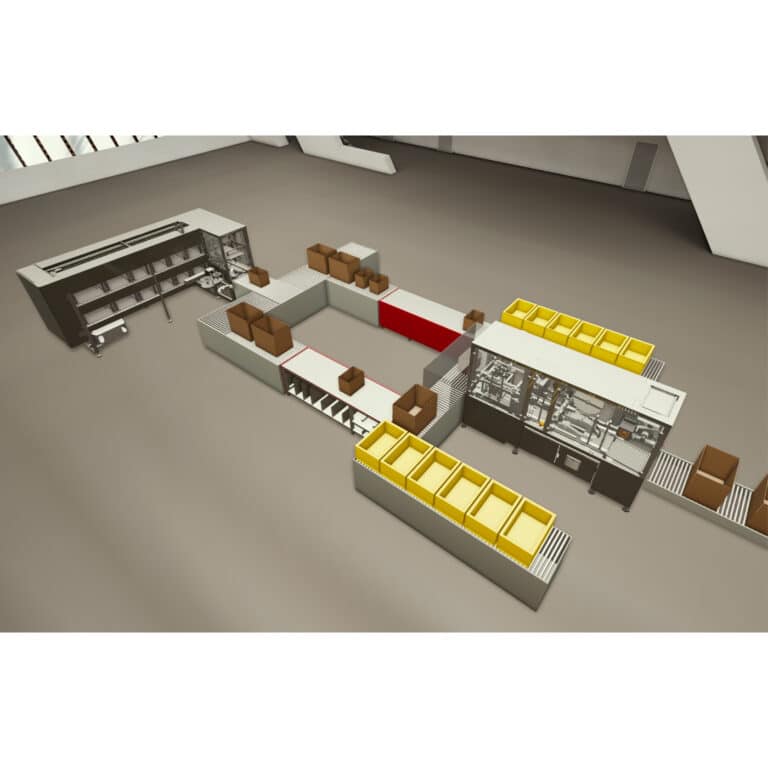

Two modules, one machine: endless configurations.

The case forming and case closing modules can operate as standalone equipment, adapting to any plant configuration.

WMS INTEGRATED PUT-TO-WALL CONFIGURATION

The E-CO FLEX FORMING case magazine offers versatile erecting capabilities in various formats, allowing for the provision of different box sizes to slipways. These boxes are then made accessible for pick-to-box operations, where operators gather multiple boxes onto a cart, promptly placing each picked product into the corresponding shipping box.

WMS INTEGRATED TOTE-BASED CONFIGURATION

The E-CO FLEX FORMING module forms, closes and divertes to the two manual packing stations.

The right-size box for the order can be selected using the customer’s WMS or measuring the volume required for the products with a dimensioning system.

After the boxes are filled, both packers take advantage of the E-CO FLEX CLOSING module with down-sizing capabilities.

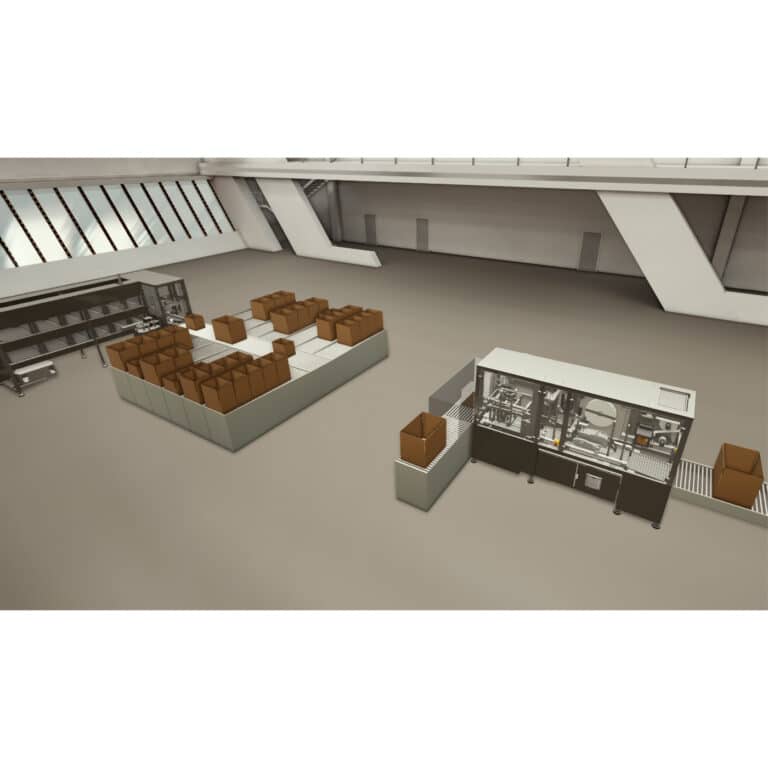

CASE ERECTING FOR PICK-TO-BOX CONFIGURATION

The E-CO FLEX FORMING case magazine offers versatile erecting capabilities in various formats, allowing for the provision of different box sizes to slipways. These boxes are then made accessible for pick-to-box operations, where operators gather multiple boxes onto a cart, promptly placing each picked product into the corresponding shipping box.

CASE ERECTING FOR RIGHT-SIZE BOX SELECTION BY OPERATOR

If the customer’s WMS does not have precise product cubing data or if the process requires operator involvement in selecting the right-size box, the E-CO FLEX proves highly beneficial. Utilizing the carton magazine, various box sizes are pre-assembled and directed onto separate slipways. Each slipway corresponds to a different box size, allowing operators to visually select the most appropriate case for each incoming order.

- Technical Data

| E-CO FLEX CLOSING | ||

| Machine speed | Up to 10 boxes/minute | |

| Box type | Standard RSC (FEFCO 201) | |

| Box dimensions | MIN | MAX |

| 7” x 6” x 3” (178 mm x 152 mm x 76 mm) |

21” x 15” x 13” (533 mm x 381 mm x 330 mm) |

|

| Adehesive technology | Water-activated (WAT) or gummed tape | |

| Print & Apply labeller | Yes, as machine option | |

| Quality inspection cameras | Yes, as machine option | |