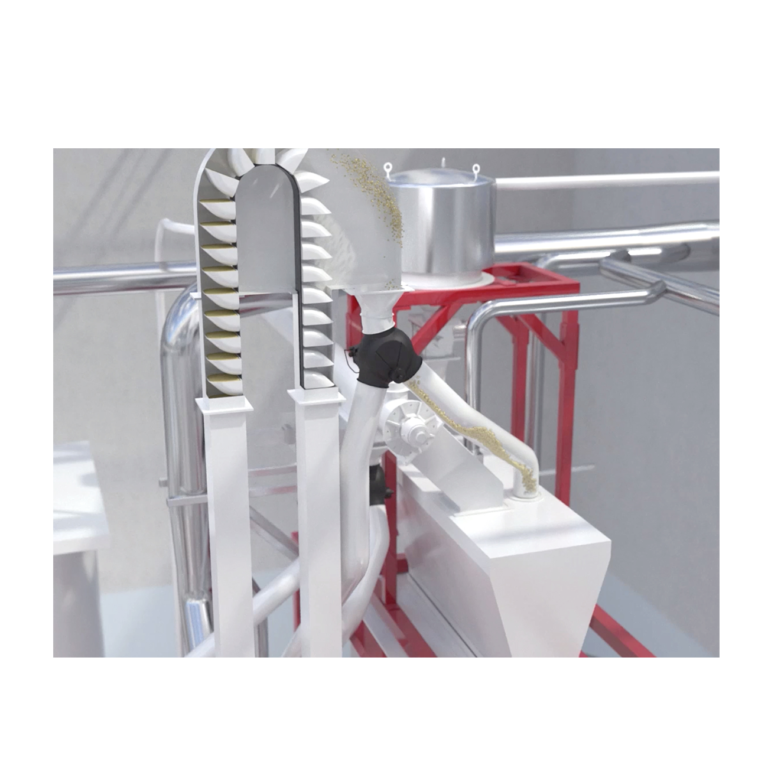

Customised plant solutions for the green coffee cleaning, tailored on the production rate and facility layout.

Customised plant solutions for the green coffee cleaning, tailored on the production rate and facility layout.

Choosing the appropriate

in-house coffee cleaning strategy

Growing costs related to ready-cleaned coffee beans and an increasing presence of impurities in green coffee have led companies to evaluate in-house treatment options. Sorting

and cleaning equipments are designed to ensure an efficient separation of the impurities, removing any type of foreign bodies up to 20 ton/h.

In facilities handling upwards of 3 tons of raw coffee per hour, an in-house cleaning solution is an astute investment, eliminating unwanted elements present in poorly cleaned coffee will significantly improve the commercial value of the end product itself. For this reason, IMA Coffee Petroncini has developed engineering solutions for cleaning plants, tailored to the most common situations. Getting the cleaning strategy right will have positive effects on the processing stages downstream. Firstly, the solution is selected according to the type and quality of product the customer receives and the capacity of the plant.

Green Coffee Cleaning and Sorting Systems Highlights

The most advanced technology to sort by shape and by colour

Today’s most advanced technology is known as optical sorting. The major benefit is its capacity to sort by shape and by colour. Combined with initial basic cleaning equipment, optical sorting is extremely effective in completing the process. Moreover, it is a versatile solution as operators can adjust the separation parameters according to the frequency and importance of the defects to be assessed and eliminated. This means taking close control over the process and consequently optimising the profits. Specific solutions have been engineered by IMA Coffee Petroncini to sort coffee in multiple passes for the most accurate cleaning and also refill big bags after the whole cleaning process has ended. Thanks to dust-tight aspiration, keeping the working area free from tiny contaminants, the coffee which may return to the big bags or be sent to the storaging silos is not only clean, but practically dust-free.