Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |IMA End-of-Line Packaging Solutions

IMA Coffee Updates

We care about your product

Reduced machine footprint and great accessibility give the machines a more contemporary feel. Attention to detail is an important part of our manufacturing philosophy. IMA End of Line also offers robotized, integrated case packing and palletizing systems that guarantee flexibility and efficiency in the increasingly demanding packaging market.

Explore Our Coffee

End-of-line Packaging Solutions

- Overwrapping

- CASE PACKING

- PALLETIZING

Overwrapping

IMA End of Line has always focused heavily on these processes and has created specific film winding, conveyor, cutting and sealing systems to ensure that the film is always cut with a geometrically precise fold and sealed without wrinkles, air bubbles or other blemishes.

The flexibility of these machines enables transverse sealing underneath the bundle or lateral sealing.

HYWRAP20

High performance overwrapping

High-speed complete wrapping machine for single or bundled products, the HYWRAP20 has been conceived as a hybrid solution capable of switching from film to paper without size changeover.

Its compact footprint and cantilever structure allow for accessibility and ease of maintenance. Servomotors are all placed on the back of the machine.

All movements are electronically driven by their own specific brushless motor for accurate performance at high speed.

The size changeover can be carried out in less than 10 minutes with few adjustments.

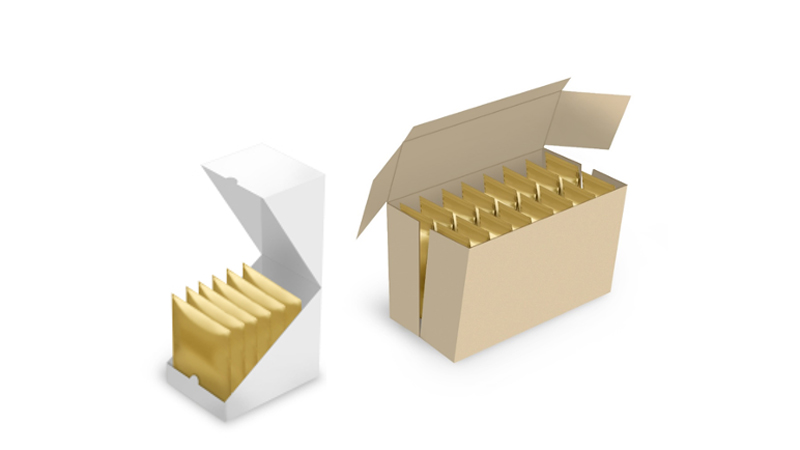

Case packing

Whichever the type of case packing you are looking for, by us you can find it!

From wrap-around to side or top loading, all our models are conceived with reduced footprints, however assuring ergonomicity and easy operator access for any type of cleaning or maintenance operations.

Any of our solution is devised to ensure total control throughout all stages of the serialization process.

Our offer includes integrated case packing and palletizing solutions in a compact structure and with an extremely simple pallet management thanks to the latest improvements in robotic technology.

MMP400

Built to pack individual or bundled products into cases, display boxes or trays starting from flat blanks, the MMP400 wrap around case packer features servo technology enabling speeds of up to 30 cases/minute and extremely smooth handling.

Ergonomically positioned components help to significantly improve operator intervention and thanks to a newly designed case erection mechanism, the horizontal case magazine is as low as possible to achieve increased autonomy. Cases are erected and held in position on two sides during loading.

Palletizing

Available in several versions ranging from basic applications, such as manual pallet loading, up to more sophisticated solutions, such as automatic feeding of empty pallets and unloading of full pallets, IMAEnd of Line palletizers have a solid structure and use precise, rapid multi-axis robotized systems for accurate positioning of products on pallets or inside “big boxes”.

Our palletizers have been developed to respond to market requirements for high speed, flexibility and compactness of the palletizing section typical of modern production lines

RP4

Smart technology for different products and tasks.

Built to deliver maximum productivity and efficiency, these latest-generation palletizing solutions offer exceptional flexibility. Based around a 6-axis robot which picks up incoming cases, ink-jet printing and labelling or weighing them, everything is carried out efficiently.

Cases are then placed on the pallet according to pre-set patterns memorised by the operator. Modular design allows for customization of the palletizing section, whose dimensions are kept to a minimum.

RP2/RP4 palletizers are conceived to be stand alone or easily integrated with case packers thanks to their quick plug-in connection.