Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |Green Coffee Handling and Conveying

Appropriate handling and conveying solutions meant to safeguard product integrity and optimise productivity.

Appropriate handling and conveying solutions meant to safeguard product integrity and optimise productivity.

Handling and conveying systems to optimise productivity

No one appreciates downtime, so any conveying issues and handling requirements are treated as key factors affecting a plant’s productivity, maximising its effectiveness. The IMA Coffee Petroncini engineering department devotes much attention to ensuring maximum efficiency connecting one process to another in the processing facility. Appropriate conveying solutions are crucial to safeguard product integrity and optimise productivity and it can guarantee the highest preservation of the quality of the product, avoiding any product contamination thanks to the Hygienic Design specifications. Petroncini’ solutions include mechanical and pneumatic conveying equipment in pression or in suction, bucket elevators, chain conveyors. Each solution is designed to suit the plant.

Green Coffee Handling and Conveying Highlights

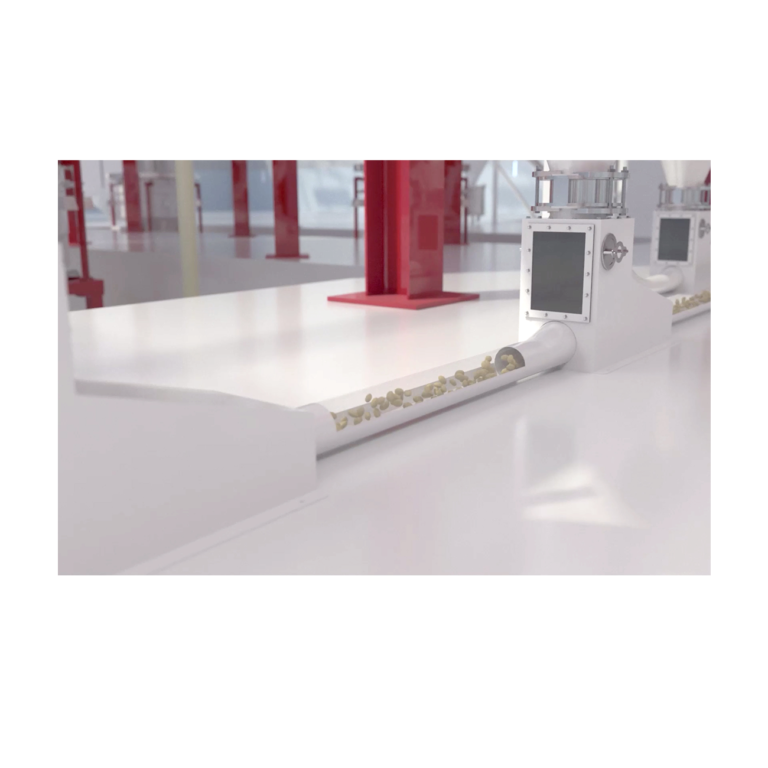

LINE-S ®

The optimisation of the space is a very determining key factor since the beginning of the engineering studies, and the solution applied to the dosing and unloading process from the silos often is the keystone of the entire project. The special dosing device LINE-S has been engineered and developed by Petroncini for maximise the energy-efficiency and the cost-effectiveness in some plant’ layout conditions.

LINE-S is an effective solution for the green bean unloading from the silos and, in a minimum amount of space, can collect several accessories for the product loading, dosing and conveying, combining sensors for the control of the system. Due to the less space footprint compared to other common valves, the using of the LINE-S dosing valves allow to save a lot of vertical space, so that it is possible to earn meter hight for each silo, corresponding to an additional storaging capacity.