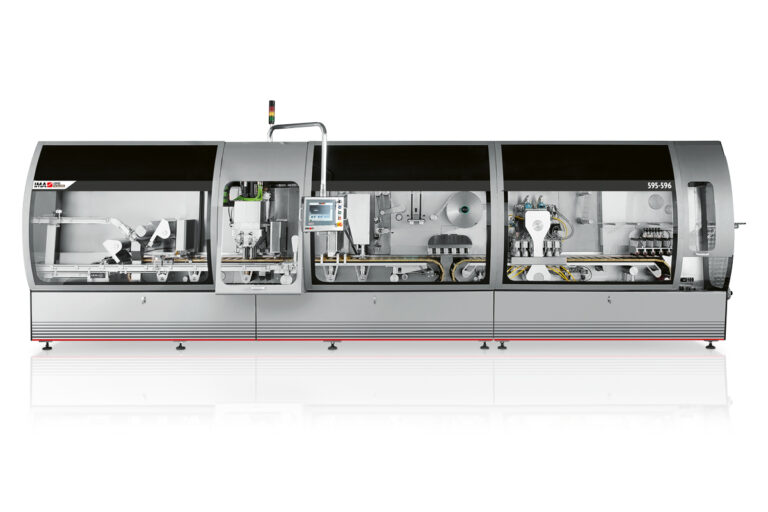

The 595 is high-speed filling and sealing machine for single serve injected and thermoformed capsules with modular concept enabling custom-made solutions for almost any kind of product.

The 595 is high-speed filling and sealing machine for single serve injected and thermoformed capsules with modular concept enabling custom-made solutions for almost any kind of product.

Any capsule you want, in less space.

The 595 handles both injected and thermoformed capsules at speeds reaching 450 capsules/minute and easily integrates the required features to run all possible single serve capsule configurations available on the market today.

The machine’s modular design also allows for a variety of sealing systems according to capsule type, materials and dosed product: cut and thermosealing for lids; cut and ultrasonic sealing for lids; assembly and ultrasonic sealing for cap closures.

The machine handles inner components to be placed and sealed inside the capsule before dosing, such as plastic filters, paper filters and bottom lids. In the drip coffee configuration, the 595 is equipped with a filter paper feeding, cutting, punching, deep-drawn pleating and sealing unit to place a pleated paper filter into the capsule.

In the case of self-protected capsules, the 595 also works in modified atmosphere using a nitrogen chamber or an autoclave (596 module).

Sustainability

|

|

| The use of ultrasonic technology for packaging material sealing guarantees energy saving if compared to traditional heat-sealing systems. The machine motorization is handled with the aim to avoid power waste. Kinetic energy generated during braking is shared and absorbed by other modules. The hermetic chamber of 595 module has been shaped around the profile of the processed capsules to assure minimum nitrogen consumption. |

The 595 can handle compostable and recyclable materials (capsule, filter, lid). |

595 Highlights

595-596

As an alternative to the nitrogen chamber, the 595 couples with the 596 oxygen extraction module, making it a compact solution with optimum machine accessibility and a hermetic chamber shaped around the capsules to assure minimum inert gas consumption.

- Technical Data

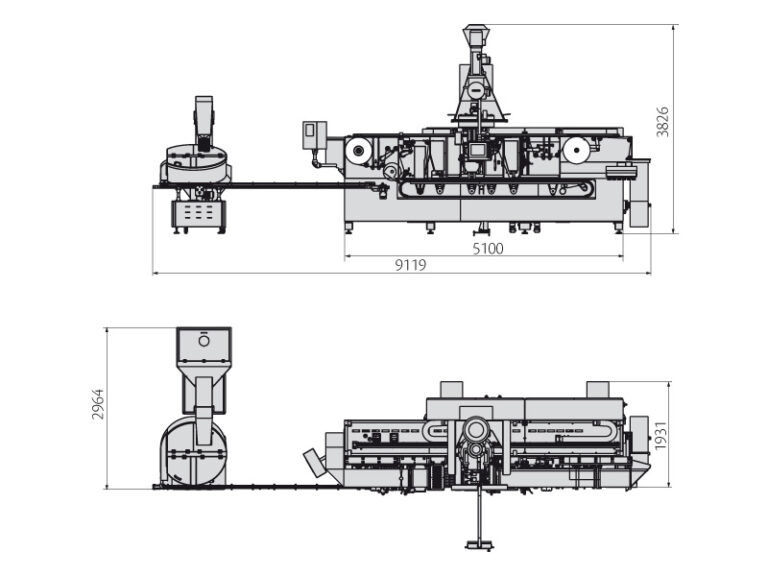

- Machine Layout

| TECHNICAL DATA 595 | ||

| Model | 595-596 | 595 |

| Production speed (6 lanes) | 480 capsules/min. – 80 cycles/min. | |

| Power Consumption | 12 kW | 8 kW |

| Machine Weight | 10,000 Kg | 7,000 Kg |

| Nitrogen consumption | 110 Nl/min. | – |

| Compressed air consumption | 410 Nl/min. | 150 Nl/min. |

| Compressed air pressure | 6 bar | |

|

Filter paper reel Lid material reel |

Max. outer diameter 500 mm – Max inner diameter 76 mm | |