Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |Today special sugar coating at our Lab!

We have been contacted by a customer with a long experience in wedding dragees: it is time to improve the process they have been doing for more than 50 years.

LAB diary. Today special sugar coating at our Lab!

We have been contacted by a customer with a long experience in wedding dragees: it is time to improve the process they have been doing for more than 50 years. They have fifteen small coating pans and a couple of operators has to run into the processing area to control each single process, manually adding the syrups when required and adjusting the drying air flow. They must ensure each piece is like all the others. It is a hard job, considering also that the process lasts days! Is it possible to reduce the operator physical effort obtaining the same product quality? Is it possible to shorten process time to be less energy consuming? Yes, sure!

This is the goal of today test on our GS 300 solid wall coating equipment, to demonstrate how a manual process can be more efficiently executed with an automated system without impacting on product quality, if not to improve it.

Last week, I carried out some internal feasibility tests on our GS 25, lab scale equipment, to get confident with the process. I understood that the

optimal machine configuration is with exhausting paddles: they are gentler with the product and, conveying the airflow into the cores bed, they give a boost for a faster drying.

Let’s start.

Almonds are tricky cores: I am apprehensive for the sharp tip, which is extremely fragile and must be protected. For this reason I have prepared an arabic gum based coating syrup. After completing the loading of the uncoated almonds, I move to the HMI.

The speed of the pan rotation, the spraying time and solution quantity, as well as the cores temperature are quickly and easily set: the sealing phase can begin. From the front door, I notice that the spray does not cover the whole length of the core bed, so I adjust slightly the spray guns position by means of the hand wheel on the guns arm.

Being a critical phase, I keep an eye on the core bed and collect samples every spraying cycle. After half an hour, as expected, the sharp tip of each almond is safe. I am now ready for the build-up.

When she contacted us, the customer shared a wish. Starch is used in the sugar coating solution to give the wedding dragee the common white color. However, when eating it, you can feel it a bit. She asked whether we could carry out the process obtaining a better taste. I had an idea: icing sugar! Yesterday, I prepared the syrup at 79 brix at 85°C without starch and I assembled on the GS 300 the powder dosing system with hopper and screw feeder. What for? Powder layering. Using which powder? Icing sugar, of course!

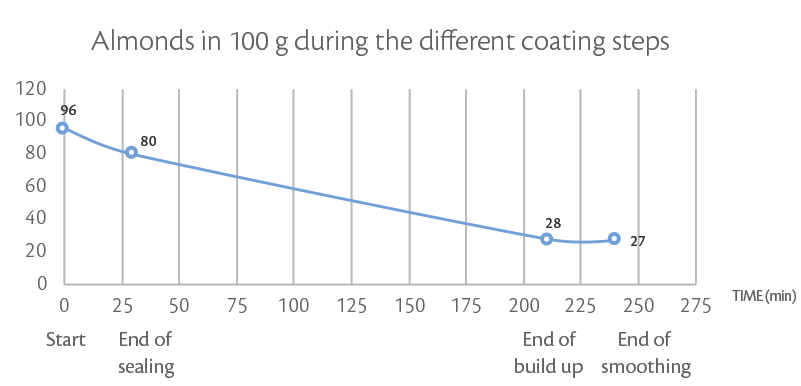

The build-up runs trouble-free. The equipment reproduces exactly what customer does in a manual mode, with the big advantage that spraying, drying, mixing and powder layering are all managed in an automatic and controlled way, performing in sequence every step of the recipe the operator sets on the HMI. After that, I go on with the smoothing phase using syrup at 66 brix. When 27 almonds together make 100 gr, the target is reached and I can finish with the polishing phase.

It took me only four hours and look at them, my wedding dragees have a very nice shape, are smooth and shining and are perfectly white!

The customer is also examining a few samples. While smiling, she bites one: “Crunchy to perfection and… delicious! Good job!”

I knew I would have made her happy. Mission accomplished!

Caterina Funaro

Coating Technologist and Process R&D Laboratory Manager at IMA Active Process Development R&D Laboratory