Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |Today is candy time at the Lab!

One of our customers is evaluating the development of a new product based on lactose free skimmed milk powder.

LAB diary. Today is candy time at the Lab!

One of our customers is evaluating the development of a new product based on lactose free skimmed milk powder. This choice is not a surprise for me: nowadays more and more food companies are improving their portfolio with allergenic-free products. Our customer is following this same trend and we are supporting the development of the new product with our competences as technologists and with our technologies.

I am involved by my colleague Federica, in charge for the tableting trials: she started compressing the powder as is, but she saw powder tending to bridge in the hopper and the tablets laminated during ejection. As it often happens, raw materials need to be granulated to improve their machinability for compression, and granulation is my daily bread.

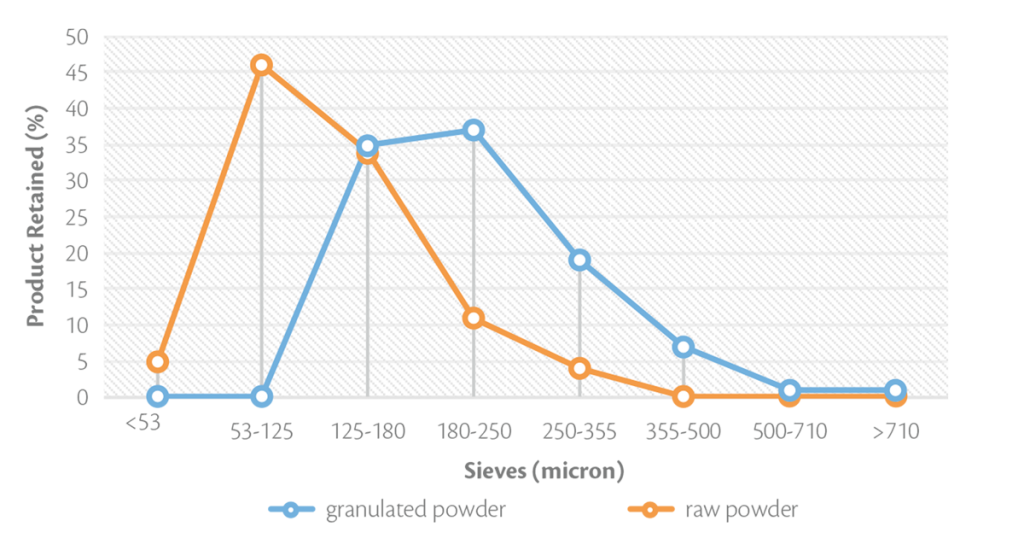

I begin characterizing the powder. Using the instrumentation available in our laboratory, I measure particle size, density, moisture content and calculate the flowability index (iCarr). At a first glance, I notice that there is a high percentage of fines. This is the first reason why we cannot obtain good tablets. Flowability is actually not bad: iCarr of 14% indicates that the powder is free flowing, but it can be better. Moisture content is less than 1%, far too low for a fat-free product. If we granulate this powder to improve particle size and moisture content, we will for sure get better results on the tablet press.

I use MYLAB, our R&D pilot scale equipment for granulation and coating. MYLAB is a modular equipment: it has a main technical unit, containing all utilities, to which two different modules can be connected, a fluid bed and a coating module. Today I connect the fluid bed module for the granulation process.

Firstly, the dispensing phase. According to the measured bulk density and considering the working capacity of the MYLAB product container, I define a batch size of 2,500 g. Respectively, I prepare also the binding solution: a dispersion of skimmed milk powder dissolved into the water. The binding power of this solution is higher than using only water and taste benefits for it as well!

Then, I go on with the granulation process itself. Once pre-heated the fluid bed, I load the raw material by gravity. Based on previous tests with similar components, I set the airflow at 130 m3/h activating the powder fluidization and the air temperature at 55° C.

The product needs to be heated up to 38° C before spraying. Then, I turn on the pump for spraying the binding solution.

This is a critical step to find the right balance among all the process parameters. However, the XIMA synoptic HMI shows clearly that the negative pression inside the chamber is increasing.

The filters may have clogged! I reduce immediately the airflow; this, together with the action of the backwashing system could clean the filters. As I do not see the parameters changing so much on the HMI, I decide to use this first tentative batch just to find out the best pump speed as well as the correct atomization parameters to be used for the new batch.

With the experience of the first batch, I prepare a second batch and start the process again. I switch on the aspirator and decrease the airflow from 130 to 100 m3/h.

The powder starts flowing gently. I set the other process parameters: air temperature, pump and atomization as found before.

I just adjust the range of pump flow rate, decreasing it from 10-15 to 8-10 ml/min to match with the lower powder flow. In just 25 minutes, the granulation process is completed. I discharge the granules and characterize them.

With respect to the raw material, the particles size of the granulated powder has increased, being in the range of 125-355 micron: we succeeded in reducing the fines. Moisture content increased as well, being up to 4.5%: this is where we wanted to get. There is no doubt that the powder characteristics have been improved.

We just have to try on the press now.

I give the granulated powder to my colleague and she immediately compress it. While raw material could not be compressed, machinability of granulated powder is smooth and trouble free: good quality candies are manufactured at the maximum machine speed. Now, customer has only to decide about the second step of its product development: should the flavor be strawberry or chocolate?

I ask Federica to give me five: great team! Mission accomplished!

Giusi Mondelli

Granulation Technologist at IMA Active Process Development R&D Laboratory