Everything gained in years of experience and expertise in the industry has been carefully channelled into PREXIMA tablet press machines. Available in three models, PREXIMA is the best solution to handle high speed tableting of candies and chewing gums.

Everything gained in years of experience and expertise in the industry has been carefully channelled into PREXIMA tablet press machines. Available in three models, PREXIMA is the best solution to handle high speed tableting of candies and chewing gums.

All our skills. Compressed.

PREXIMA can process a wide range of pressed sweets shapes and sizes on the same machine. Simply replace compression tooling to change to a different size of the same pressed sweets or to a different design to enhance marketing differentiation. On PREXIMA 800, bilayer candies and chewing gums can be manufactured.

PREXIMA Highlights

- Technical Data

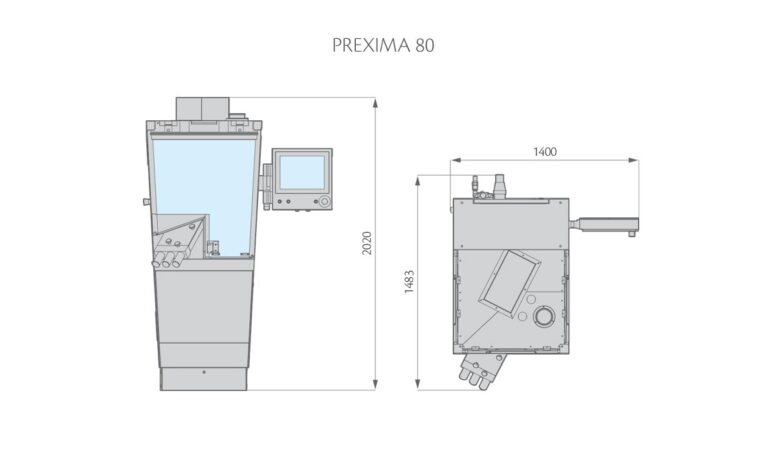

- Machine Layout

| TECHNICAL DATA PREXIMA 80 | ||||

| Die type | B+D | D | B | BB |

| Tool type (EU and TSM) | B+D | D | B | B |

| Number of press stations | 4+4 | 13 | 16 | 19 |

| Maximum table diameter (mm) | 16+25 | 25 | 16 | 13 |

| Maximum die filling (mm) | 18 | |||

| Maximum output (tbl/min) | 340 | 1,105 | 1,360 | 1,615 |

| Revolution per minute (-1) | 85 | |||

| Maximum pre-compression force (kN) | 10 | |||

| Maximum compaction force (kN) | 60 | |||

| Electrical power requirement (kW) | 7,5 | |||

| Standard voltage | 400V (+/- 10%) 50-60 Hz | |||

| TECHNICAL DATA PREXIMA 300 | PREXIMA 300 T | |||||||

| Die type | IMA 32 | D | B | BB | IMA 8 | IMA 32 T | ||

| Tool type | IMA 32 | D | B | IMA 8 | IMA 32 T | |||

| Maximum tablet diameter (mm) | 39 | 25 | 16 | 13 | 10 | 39 | 49 | |

| Number of press stations | 18 | 27 | 33 | 41 | 55 | 20 | 18 | |

| Maximum output (tbl/min) | 1,620 | 3,240 | 3,960 | 4,920 | 396,000 | 1,800 | 1,620 | |

| Maximum speed (rpm) | 90 | 120 | 90 | |||||

| Maximum die filling (mm) | 24 | 19 | 40 | |||||

| Maximum tablet thickness (mm) | 1.5-12 | 1.5-10 | 20 | |||||

| Maximum pre-compression force (kN) | 100 | |||||||

| Maximum compaction force (kN) | 100 | |||||||

| Electical power requirement (kW) | 14 | |||||||

| Standard voltage | 400V (+/- 10%) 50-60 Hz | |||||||

| TECHNICAL DATA PREXIMA 800 | PREXIMA 800T | |||||

| Die type | D | B | BB | BBS | IMA 8 | IMA 32 T |

| Tool type (EU and TSM) | D | B | IMA 8 | IMA 32 T | ||

| Maximum tablet diameter (mm) | 25 | 16 | 13 | 11 | 10 | 39 |

| Number of press stations | 53 | 65 | 81 | 87 | 105 | 39 |

| Maximum output (tbl/min) monolayer | 4,770 | 5,850 | 7,290 | 8,700 | 21,000 | 3,900 |

| Maximum output (tbl/min) bilayer | 286,200 | 351,000 | 437,400 | 522,000 | 10,500 | 1,950 |

| Maximum speed (rpm) | 90 | 100 | 100 | 50 | ||

| Maximum die filling (mm) | 20 | 19 | 40 | |||

| Maximum tablet thickness (mm) | 1.5-10 | 20 | ||||

| Maximum pre-compression force (kN) | 100 | |||||

| Maximum compaction force (kN) | 100 | |||||

| Electrical power requirement (kW) | 27 | |||||

| Standard voltage | 400V (+/- 10%) 50-60 Hz | |||||