Designed to bundle bottles or cartoned bottles and shrink wrap them with PE film in the extremely compact T600 tunnel, the MS560 ensures time-saving efficiency, ergonomics, ease-of-use and top quality execution.

Designed to bundle bottles or cartoned bottles and shrink wrap them with PE film in the extremely compact T600 tunnel, the MS560 ensures time-saving efficiency, ergonomics, ease-of-use and top quality execution.

Efficient processing with downtime kept at minimum.

Built ergonomically and with maximum accessibility to facilitate cleaning procedures and maintenance, the MS560 ensures smooth, accurate product handling at speeds of up to 40 cycles/min thanks to servo-driven technology.

Reel change times can be totally eliminated with an optional automatic film splicing device, putting the accent on efficiency as well as accuracy.

MS560 Highlights

- Technical Data

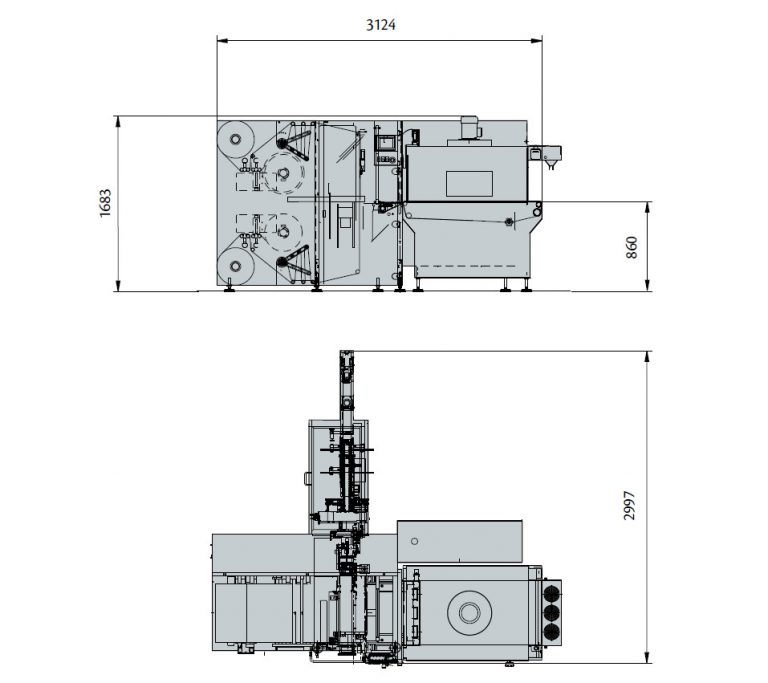

- Machine Layout

| TECHNICAL DATA MS560 | |||

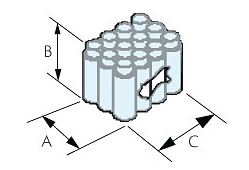

| Product dimensions | A | B | C |

| Min. | 60 | 30 | 60 |

| Max. | 220 | 210 | 400 |

| Max. speed | 40 | ||

| Wrapping film | PE 40-70 micron | ||