Quick access to IMA Sectors:

Pharma | Food & Dairy | Confectionery | Tea & Beverage | Coffee | Personal & Home Care | Tissue & Nonwoven | Automation | Tobacco | E-Commerce |GS

Suitable to meet the requirements of the confectionery industry, GS features innovative technology ensuring energy saving and reliability. Available in different models, GS machines allows the coating of all product shape and sizes.

Suitable to meet the requirements of the confectionery industry, GS features innovative technology ensuring energy saving and reliability. Available in different models, GS machines allows the coating of all product shape and sizes.

The coating pan that made history.

GS is the ideal solution for all manufacturing needs: powder layering, film and sugar coating. Flexibility is the hallmark of GS, providing smart solutions to maximise efficiency in sugar coating and powder layering processes. Patented exhausting or blowing paddles convey the drying air through the cores bed. This makes for the reduction of process times and thus the air volume needed. Suitable for non-pareille, sprinkles, gums, candies, chocolate cores, jelly beans and dried fruit.

GS Highlights

Lab Version.

MYLAB is a laboratory-scale coating pan processor for R&D purposes equipped with an interchangeable drum, either fully perforated or solid wall. The drum is able to work batches from 1.5 to 6 litres, a smaller drum to work from 0.5 to 2 litres is also available as an option.

- Technical Data

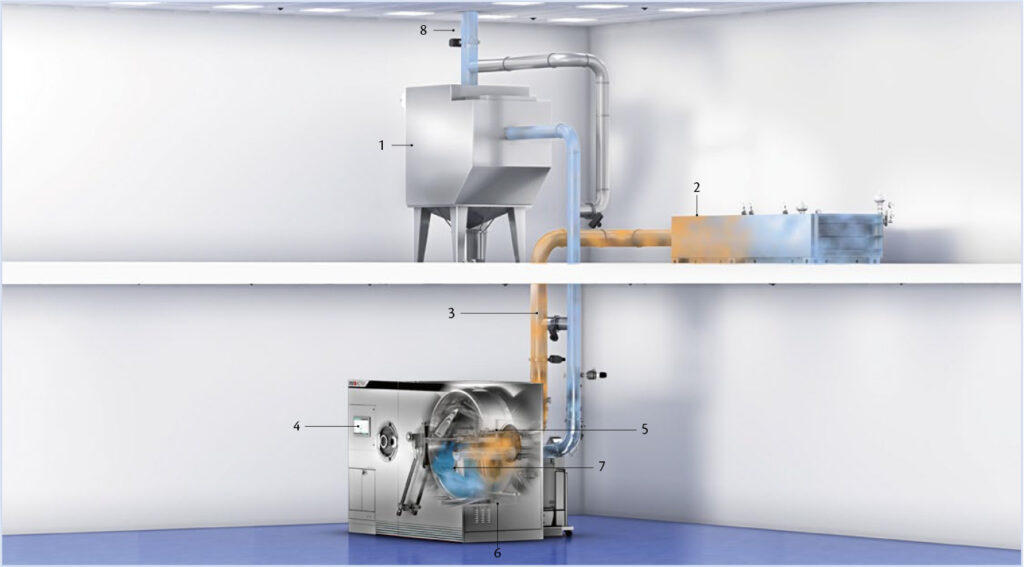

- Machine Layout

| TECHNICAL DATA GS | ||||||||

| Model | GS 25 | GS 70 | GS 150 | GS 300 | GS 400 | GS 450 | GS 600 | GS 700 |

| Minimum/maximum capacity (litres) | 13÷25 | 40÷70 | 70÷150 | 150÷300 | 200÷400 | 225 ÷ 450 | 350 ÷ 650 | 350 ÷ 700 |

| Pan diameter (mm) | 800 | 1,050 | 1,280 | 1,580 | 1,630 | 1,700 | 2,000 | 2,050 |

| Pan mouth diameter (mm) | 300 | 400 | 450 | 520 | 730 | |||

| Pan motor power (kW) | 0.37 | 1.1 | 1.5 | 3 | 4 | 5.5 | ||

| Process air delivery (m³/h) | 350 | 1,000 | 1,400 | 2,500 | 3,000 | 4,000 | ||