High-speed overwrapping machines for single and multiple products. The FTO513 Series, which can handle up to 300 ppm, features a number of technically advanced solutions to ensure tamper-evidence top quality package appearance.

High-speed overwrapping machines for single and multiple products. The FTO513 Series, which can handle up to 300 ppm, features a number of technically advanced solutions to ensure tamper-evidence top quality package appearance.

High-speed overwrapping for

perfect-looking packs

Despite its high-speed processing, the FTO513, which can handle up to 330 ppm, features a number of technically advanced solutions to ensure top quality appearance of the packages.

These include an inline tear-tape unit, a double reel holder and an automatic film splicing device.

Products will benefit from the high-quality overwrapping standards obtained on the FTO513 in terms of moisture protection and extended shelf life (especially on the model ensuring airtight sealing), tamper evidence and enhanced external packaging appearance.

Sustainability

|

|

| Shared bus with power exchange for consumption optimization. The motorization is handled with the aim to avoid power waste. Kinetic energy generated during braking is shared and absorbed by other modules of the machine, reducing the overall power consumption. | It allows the use of sustainable packaging materials for an eco-friendly package. |

FTO513 Series Highlights

- Technical Data

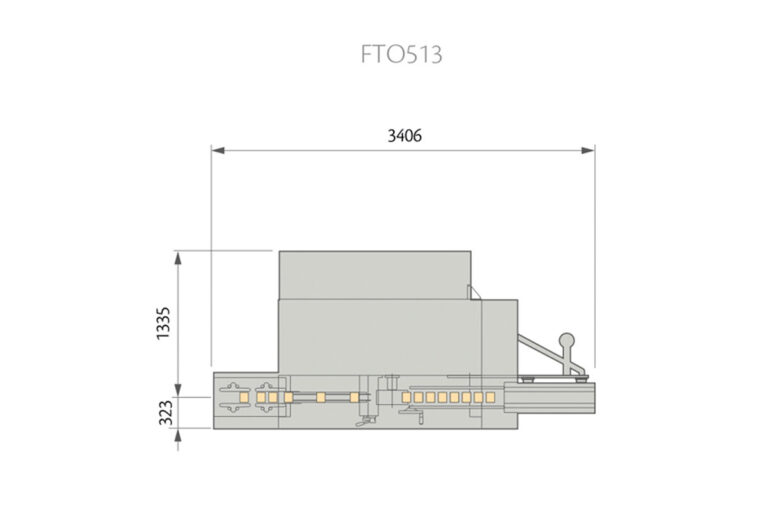

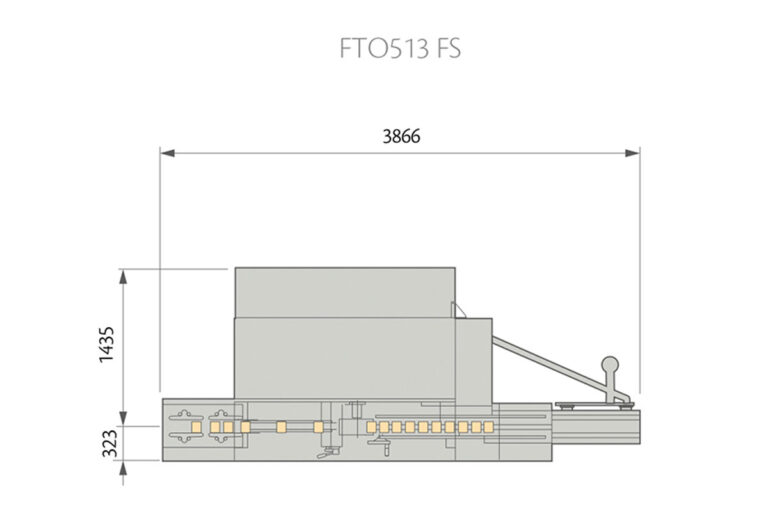

- Machine Layout

| TECHNICAL DATA FTO513 | ||||

| Production range (mm) | A | B | C | |

| FTO513 | Min. | 30 | 6 | 55 |

| Max. | 115 | 36 | 160 | |

| FTO513 Fin Seal |

Min. | 30 | 6 | 55 |

| Max. | 115 | 30 | 160 | |

| Production Speed | Up to 300 products/min | |||

Sizes out of range can be handled after been evaluated from technical office.