Prime technology, intelligent design, enduring reliability. The GMP compliant design of IMA fluid bed granulators allows for maximum product yield, while reducing maintenance and cleaning time to a minimum.

Prime technology, intelligent design, enduring reliability. The GMP compliant design of IMA fluid bed granulators allows for maximum product yield, while reducing maintenance and cleaning time to a minimum.

The prime element in fluid bed processing.

Simplified processing concepts based on smart design as well as repeatable and reliable process operations thanks to precise process control are the key features of ARIA fluid bed processors. ARIA con be installed in line with high shear mixer granulators for the drying of wet masses. With appropriate accessories, it can run as stand-alone equipment for granulating and coating small cores.

ARIA Highlights

Lab Version.

Mylab is a laboratory-scale processor for R&D purposes, suitable for drying, granulation and coating of cores. The product containers can work batch sizes from 3 to 6 litres.

- Technical Data

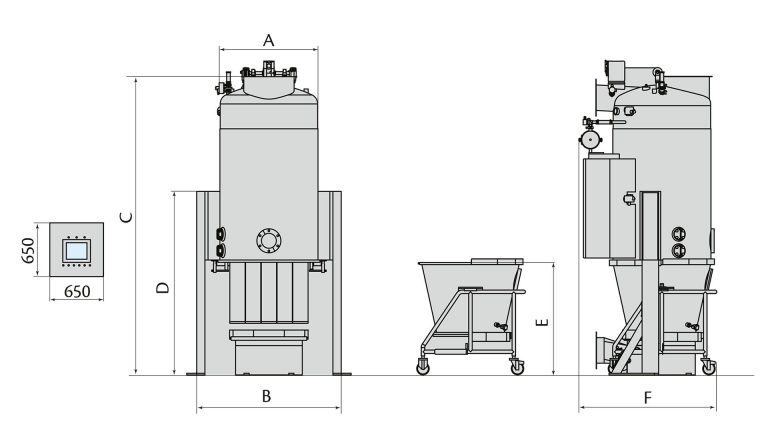

- Machine Layout

| TECHNICAL DATA ARIA | ||||||||

| Model | 60 | 120 | 300 | 600 | 900 | 1200 | 1500 | 2000 |

| Recommended batch size (kg) | 25 | 50 | 120 | 250 | 400 | 500 | 600 | 800 |

| ROTO MIX inline (l) | 60 | 120 | 300 | 600 | 900 | 1,200 | 1,500 | 2,500 |

| A (mm) | 590 | 700 | 960 | 1,190 | 1,410 | 1,740 | 1,800 | |

| B (mm) | 1,150 | 1,260 | 1,520 | 1,750 | 2,040 | 2,300 | 2,800 | |

| C (mm) | 2,500 | 2,790 | 3,235 | 3,615 | 4,100 | 5,670 | 6,300 | |

| D (mm) | 1,775 | 1,775 | 1,840 | 2,220 | 2,675 | 3,785 | 3,800 | |

| E (mm) | 1,010 | 1,010 | 1,050 | 1,360 | 1,530 | 1,900 | 2,150 | |

| F (mm) | 1,420 | 1,420 | 1,560 | 1,610 | 1,830 | 2,160 | 2,600 | |