The ideal solution for just-in-time production of small-medium batches, handling any blister/product shape and configuration. With GIANT1 Series you choose the state of the art technology in terms of design, feeders, quality controls and servomotors.

The ideal solution for just-in-time production of small-medium batches, handling any blister/product shape and configuration. With GIANT1 Series you choose the state of the art technology in terms of design, feeders, quality controls and servomotors.

The excellence that our users have come to expect

GIANT1 Series grants the widest flexibility in terms of product shape, blister sizes and configurations.

An important benefit that GIANT1 offers to you is the IMA patented Sombrero, the most versatile and efficient universal feeder. Moreover, to satisfy all requirements for containment of solid pharmaceutical shapes in blister packaging, the feeding area is already designed for containment application.

GIANT1 Series is also an extremely compact line, with a unique design, able to give a linear workflow and an overall visibility of the material work to the operator.

Sustainability

|

|

| Energy consumption is reduced to a minimum. | Compatibility with the use of recyclable / compostable materials. |

GIANT1 Highlights

Versions

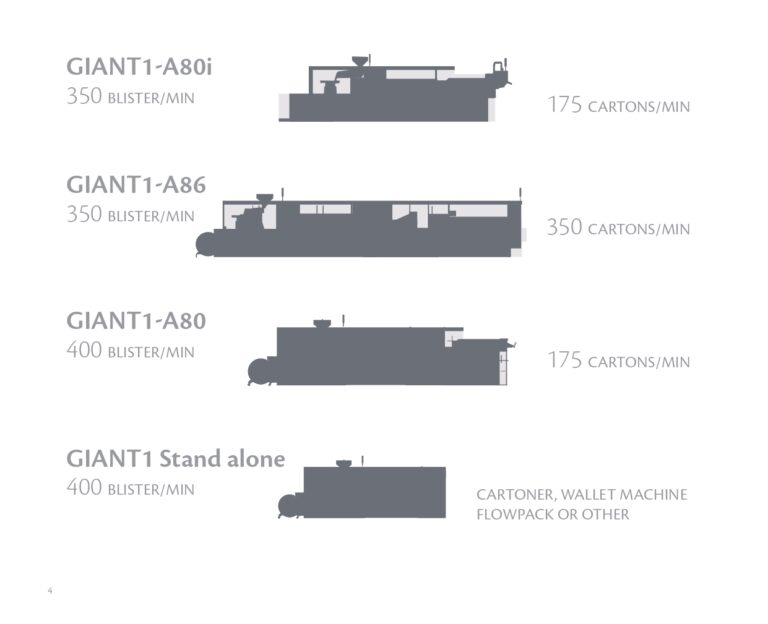

The GIANT Series is available in four versions:

- GIANT1- A80i, integrated blister and cartoner, with positive blister transfer – 350 blisters/minute and 175 cartons/minute

- GIANT1-A86, integrated blister and cartoner, with positive blister transfer – 350 blisters/minute and 350 cartons/minute

- GIANT1-A80, integrated blister and cartoner, connection by means of magazine – 400 blisters/minute and 175 cartons/minute

- GIANT1 Stand alone

The GIANT1 can be easily connected to any other downstream packaging machine (cartoner, wallet packer, flowpacker or end-of-line) in order to satisfy any customer production needs.

- Technical Data

- Machine Layout

| TECHNICAL DATA GIANT | ||||

| Blister dimensions | Carton dimensions | |||

| Width | 30-90 mm | 35-97 mm | ||

| Length | 60-145 mm | 65-154 mm | ||

| Depth / Height | 3-12 mm | 12-106 mm | ||

| Production output | ||||

| Model | GIANT1 | GIANT1-A80i | GIANT1-A86 | GIANT1-A80 |

| Blisters | up to 400 blisters/min. | up to 350 blisters/min. | up to 350 blisters/min. | up to 400 blisters/min. |

| Cartons | / | up to 175 cartons/min. | up to 350 cartons/min. | up to 175 cartons/min. |